Maintenance Made Simple

Empowering operations and maintenance teams to maximise operational uptime and deliver lasting value to your business.

Increased Uptime

Boost equipment reliability and operational efficiency with our CMMS, ensuring maximum uptime and minimal disruptions.

Improved MTBF

Improve Mean Time Between Failures (MTBF), ensuring your equipment runs smoothly & efficiently with fewer interruptions.

Decreased MTTR

Minimize Mean Time to Repair (MTTR), enabling faster response times and quicker resolutions for smooth operations.

Technician Satisfaction

Increase technician satisfaction by providing streamlined workflows, leading to a more efficient work environment.

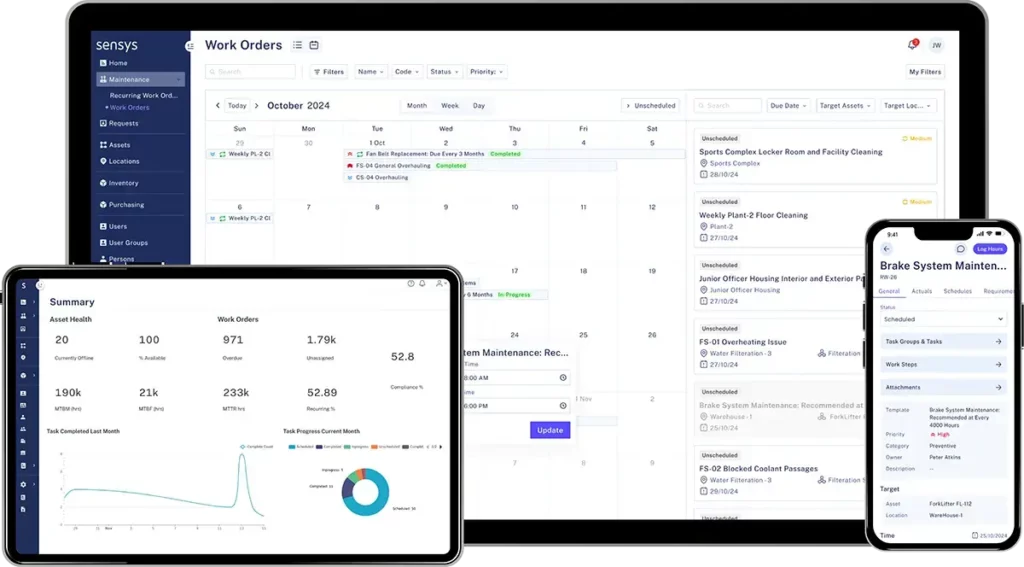

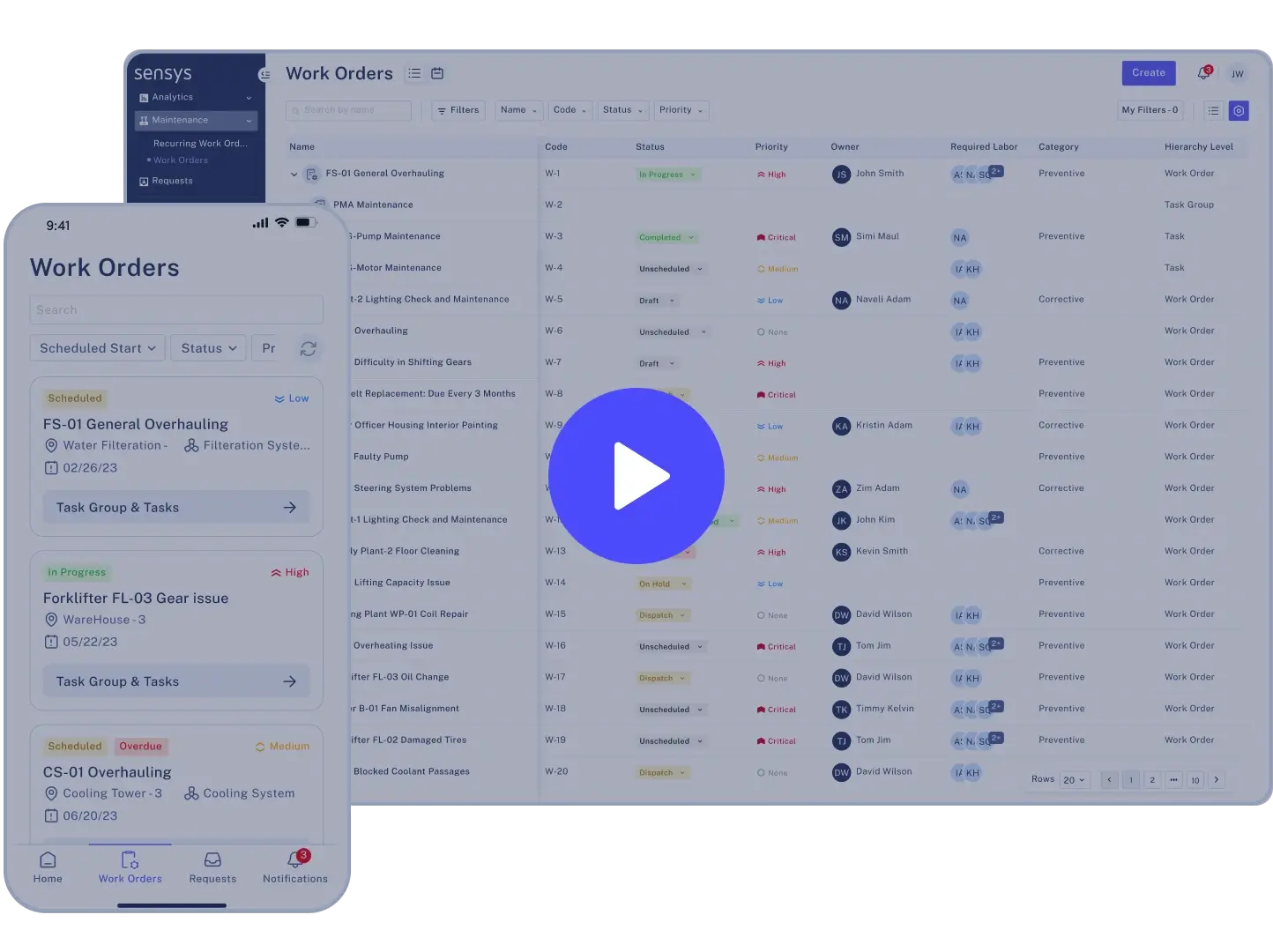

Sensys in Action

Watch how Sensys simplifies maintenance management and drives operational excellence.

A Powerful & Feature-rich Platform

Sensys simplifies your workflows and prepares you for success in a world moving towards smart industries.

Covering The Entire

Maintenance Lifecycle

Effectively Plan, Easily Schedule, Effortlessly Execute

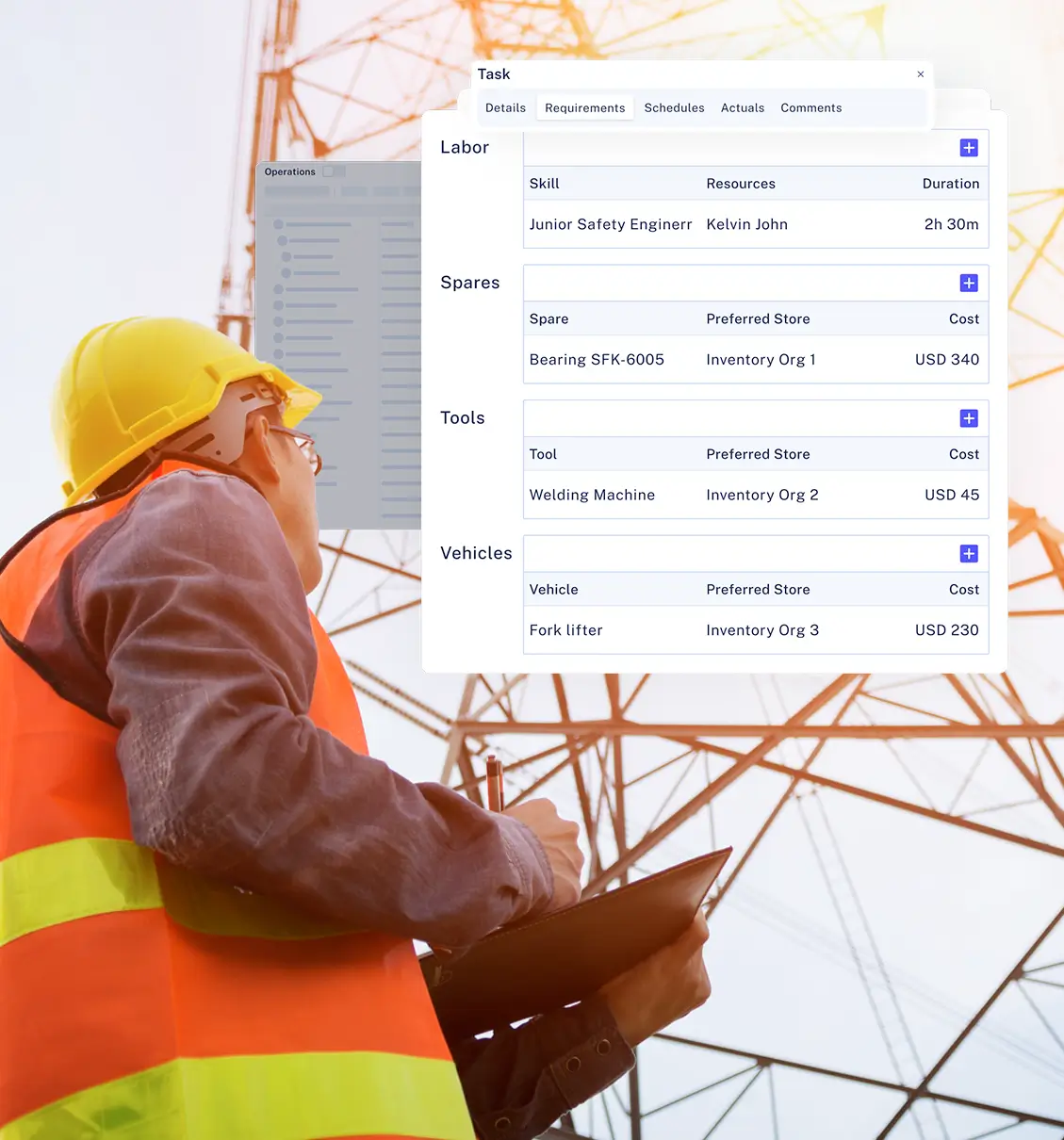

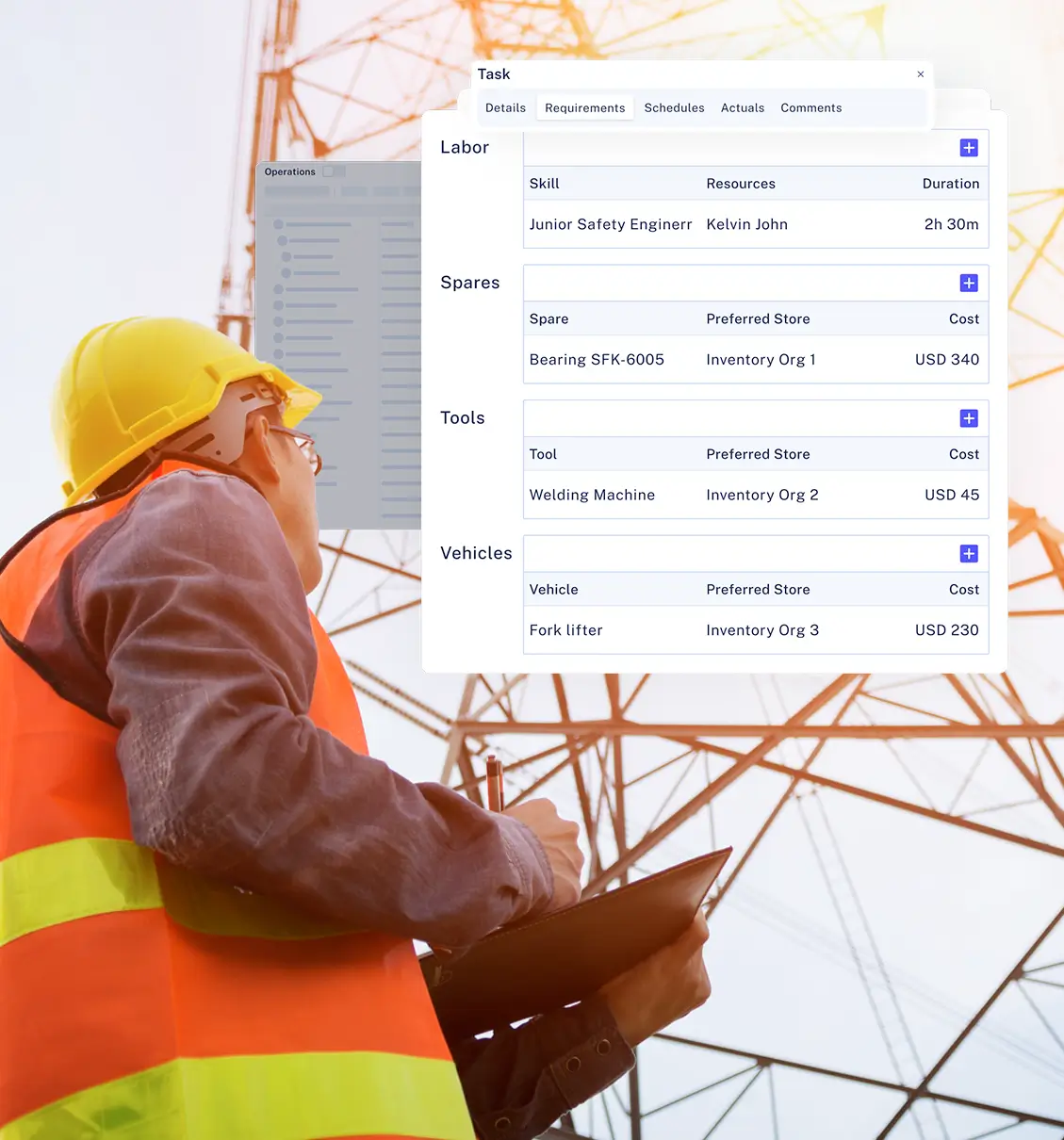

Planning

Strategic

Maintenance Planning

Effective planning starts with visibility. Whether its work requests, the number of tools in the store, or the individuals in your maintenance team, Sensys gives you all this information at your fingertips and provides the foundation for efficient maintenance operation.

Scheduling

Optimized

Maintenance Scheduling

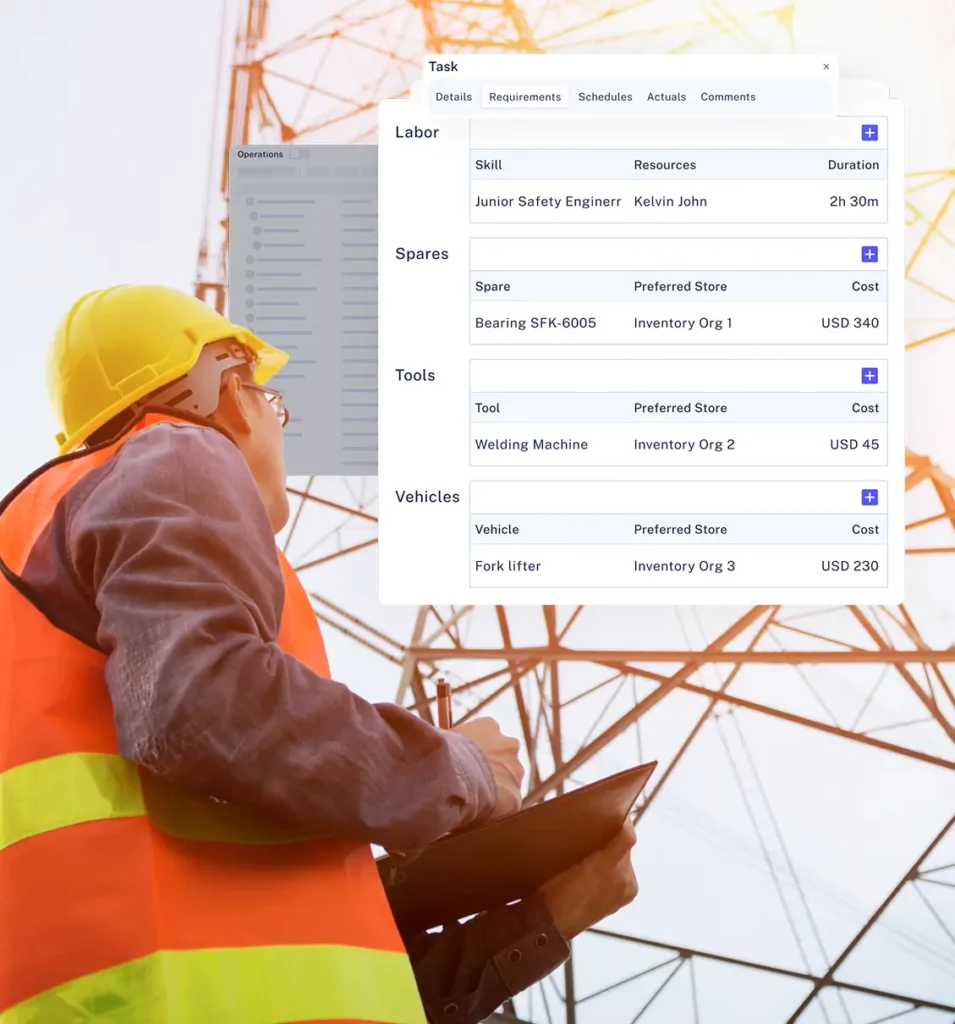

Maintenance organizations face the challenge of balancing demand with the supply of people, spares, and tools. Sensys allows you to schedule any resource, including generic skills, so that you can plan your maintenance activities well in advance and get ahead of demand.

Execution

Efficient

Maintenance Execution

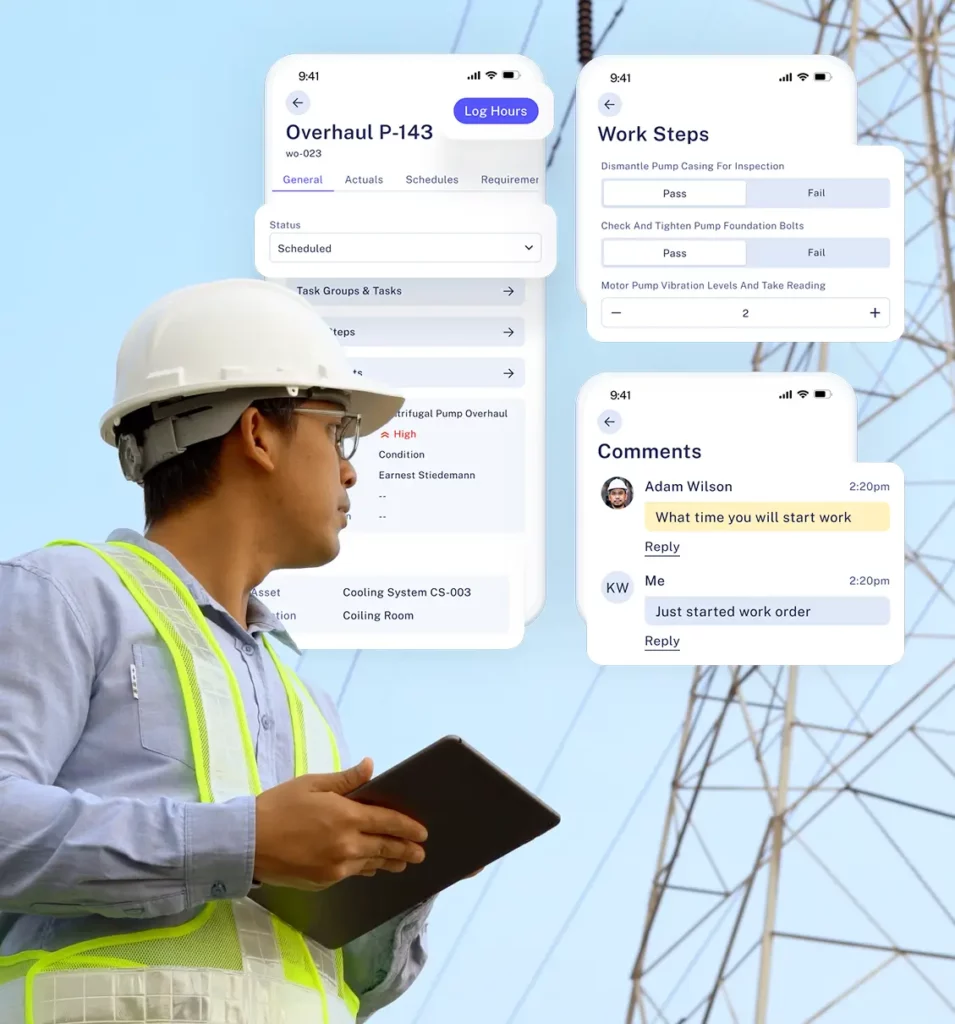

When it’s time to work in the field, Sensys’ mobile application lets technicians know exactly what they should work on and the steps to reliably execute maintenance activities.

Planning

Strategic

Maintenance Planning

Effective planning starts with visibility. Whether its work requests, the number of tools in the store, or the individuals in your maintenance team, Sensys gives you all this information at your fingertips and provides the foundation for efficient maintenance operation.

Scheduling

Optimized

Maintenance Scheduling

Maintenance organizations face the challenge of balancing demand with the supply of people, spares, and tools. Sensys allows you to schedule any resource, including generic skills, so that you can plan your maintenance activities well in advance and get ahead of demand.

Execution

Efficient

Maintenance Execution

When it’s time to work in the field, Sensys’ mobile application lets technicians know exactly what they should work on and the steps to reliably execute maintenance activities.

Digital

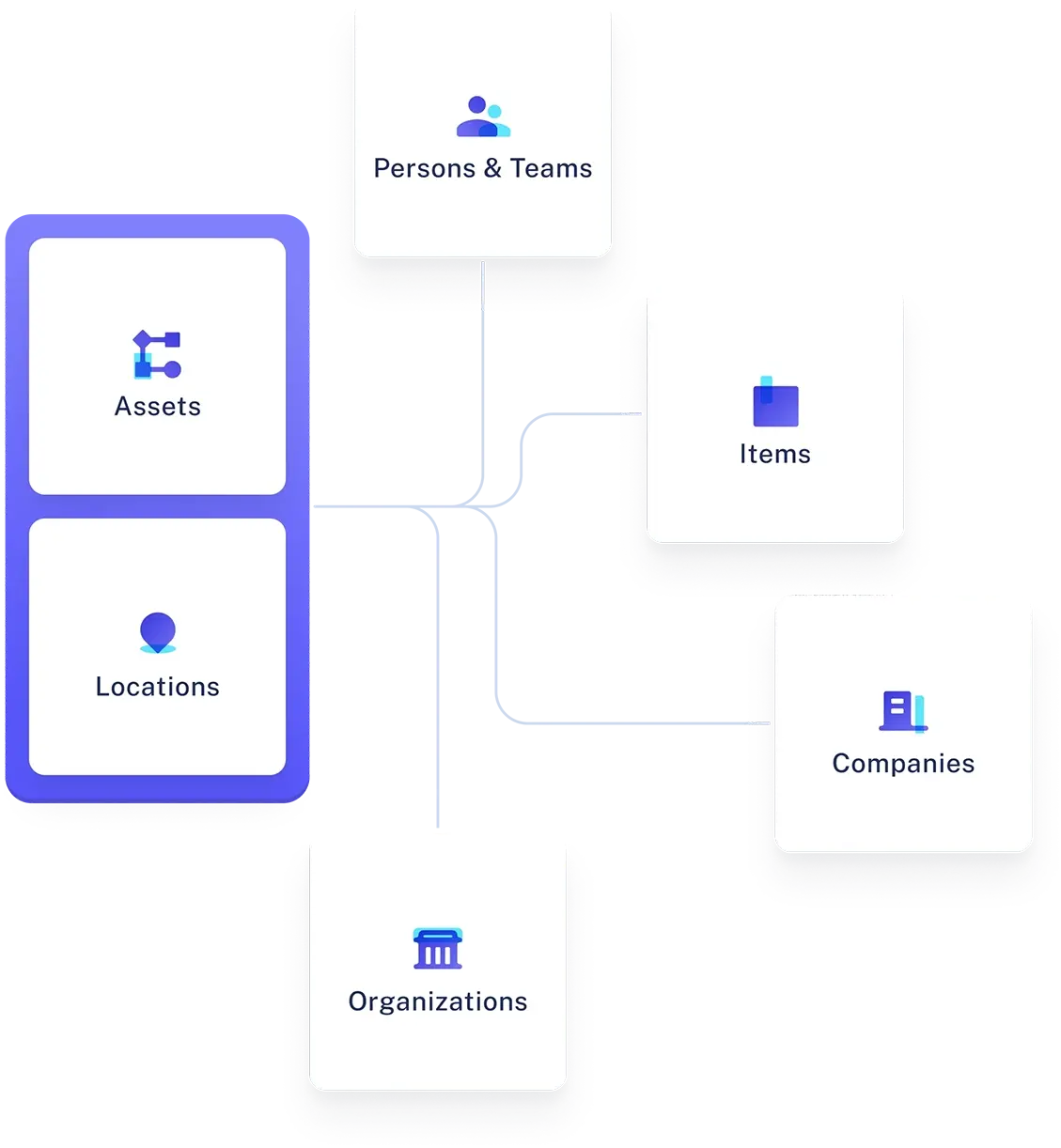

Operations Twin

Our Digital Operations Twin brings your maintenance ecosystem together and empowers agile decision-making, predictive maintenance, and optimization of workflows.

Intuitive

User Experience

Most maintenance and asset management applications are complicated and difficult to use. At Sensys, we’ve poured our energy into innovating in user experience, giving you a simple digital experience without compromising on features.

Helping maintenance and service teams succeed

Creating Value for Every Role

in Your Organization

A tailored solution that enhances productivity, streamlines workflows,

and supports decision-making at all levels.

See reports of all your maintenance activity through a wide range of filters from Asset to Location to Business Division

Track down-time and maintenance spend to assess the reliability of your facility’s operations and the efficiency of your maintenance activity

Get a real-time view of your past, current, and future maintenance activity through customizable filters

See the entire digital catalog of your asset base down to the equipment component level

Manage your team’s competency through skills and qualifications

Track the tools, including vehicles, required to perform reliable maintenance activity

Design work order templates and task groups so that your field personnel follow best practices when conducting any type of maintenance activity

See all of your upcoming work requests in an easy-to-use grid view, and filter across a range of categories

Easily reserve and schedule any maintenance resource (personnel, vehicles, other tools, spares, etc.)

Get the latest updates from field personnel through comments, images, and other attachments

Only see the work orders that are relevant to you

Upload comments, images, and attachments directly onto individual work orders, including from your mobile device

Know exactly what steps you need to follow for repeatable and reliable maintenance activity through work

Log activity time, down to the individual task level

See reports of all your maintenance activity through a wide range of filters from Asset to Location to Business Division

Track down-time and maintenance spend to assess the reliability of your facility’s operations and the efficiency of your maintenance activity

Get a real-time view of your past, current, and future maintenance activity through customizable filters

See the entire digital catalog of your asset base down to the equipment component level

Manage your team’s competency through skills and qualifications

Track the tools, including vehicles, required to perform reliable maintenance activity

Design work order templates and task groups so that your field personnel follow best practices when conducting any type of maintenance activity

See all of your upcoming work requests in an easy-to-use grid view, and filter across a range of categories

Easily reserve and schedule any maintenance resource (personnel, vehicles, other tools, spares, etc.)

Get the latest updates from field personnel through comments, images, and other attachments

Only see the work orders that are relevant to you

Upload comments, images, and attachments directly onto individual work orders, including from your mobile device

Know exactly what steps you need to follow for repeatable and reliable maintenance activity through work

Log activity time, down to the individual task level

The Sensys Experience

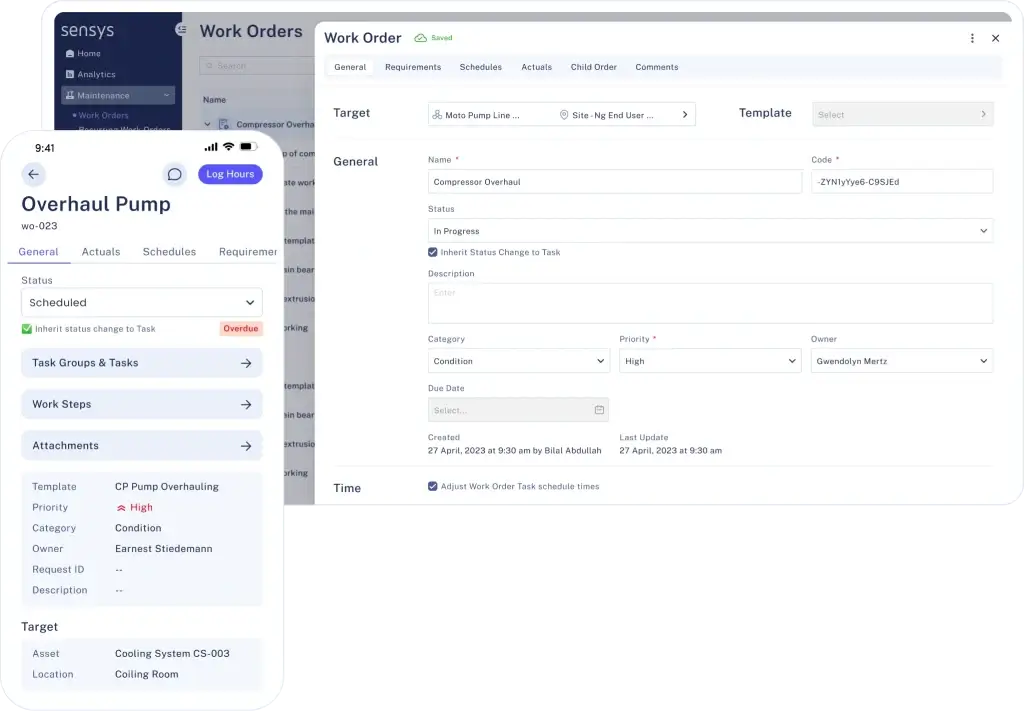

A comprehensive work order form allows you to capture an extensive list of properties, track labor costs, reserve tools and spares, and collaborate with members across your organization.

One of the richest Digital Twins in the world, giving the ability to model Assets, Locations, Teams, Tools, and Spares

Sensys allows you to schedule work orders and resources (personnel, vehicles, tools, spares) in advance, giving your planner and dispatcher the ability to assign and prioritize work as per the most urgent needs of the organization.

Sensys gives you the power to design templates around your maintenance best practices, for example – Task Groups allow you to ensure each work order for pump replacement contains the same tasks or steps as it is created.

If our base application is missing an important property, you can still capture it using our Custom Properties feature.

Sensys tracks the cost of both spares and labor associated with each work order. Our Inventory module allows you to assign a cost to each spare as well as a cost / hour for each resource used, for example, labor cost per hour.

Sensys allows maintenance organizations to track the Skills and Qualifications of their individual field personnel. This helps ensure that your organization has the proper competency to provide reliable service, and that qualified personnel are assigned to relevant maintenance activities.

Sensys provides extensive collaboration within the work order form itself, allowing users to share comments and upload files such as PDFs and images. Real-time notifications provide relevant users with timely updates allowing your teams to resolve issues quickly.

Sensys comes packaged with a pre-built set of analytical dashboards covering crucial KPIs such as total and open work orders, average cycle time, estimated hours, and total maintenance cost, amongst others